Revolutionise Your Packaging Process with Compak's Vertical Stretch Wrapping Machines

Semi Automatic stretch wrap machines

The application of the film, with the use of semi automatic stretch wrap machines takes place with the supervision and the intervention of the operator. He will position the pallet and connects the LLDPE film manually, followed by starting the pre-set wrapping cycle, to be finished with the final manual cut by the operator or by the optional installed mechanical cutter.

The operator will unload the pallet and store or load it into a truck for further shipment.

Semi automatic stretch wrap machines are divided on base of operation and structure in:

- Rotating turntable machines

- Rotary arm machines

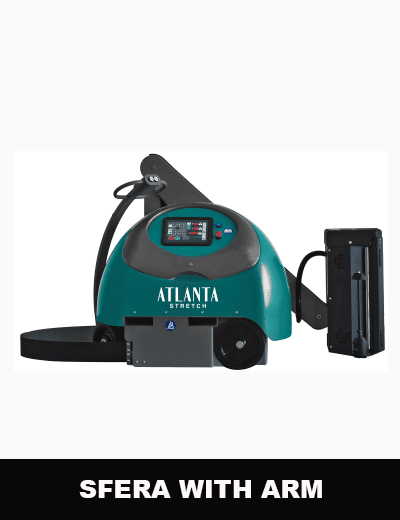

- Mobile wrapping machines

One of the most important informations required, is the needed productivity and the type of products that shall be packed. On base of height, weight, stability and needed productivity, it will be possible to identify the most optimal configuration for the machine.

Generally, it is not advisable to use a Rotating turntable machine, if the pallets are instable. Even though an optional top-presser unit, that facilitates the holding of the product is available.

If you are searching a product with higher performances for instable pallets the focus should be directed on our rotary arm machines.

If you are packing pallets with extraordinary forms and shapes, the Mobile wrapping machines could be the solution which are fitting the request.

All products are manufactured according to the EC Standards and are marketed throughout the world.

Compak offers a comprehensive range of Vertical Stretch Wrapping Machines designed to elevate your packaging efficiency and ensure the secure transit of your products. From the versatile Robot Master to the high-performance RotoWrap series and the innovative EcoPlat line, our machines cater to diverse needs across industries.